For CT-2

| Created by | Borhan |

|---|---|

| Last edited time | |

| Tag |

Topic 01: Fiber Fabrication

Definition: Fiber Fabrication is the process of manufacturing long, thin, flexible strands (optical fibers) made of high-purity glass (silica) to guide light signals over long distances with minimal loss.

1. Materials for Fiber Fabrication

Starting Materials:

- Main Material: Silica (SiO₂), derived from Silicon Tetrachloride (SiCl₄).

- Dopants (to modify properties):

- GeCl₄ (Germanium Tetrachloride): Increases refractive index.

- TiCl₄ (Titanium Tetrachloride): Enhances specific optical properties.

- BBr₃ (Boron Tribromide): Decreases refractive index.

- Purity Requirement: Transition metals (e.g., iron, copper) must be below 10 ppb (parts per billion) to avoid light absorption, which weakens the signal.

Mnemonic: "SGTB" (Silica, Germanium, Titanium, Boron) – Think of a Super Glass Tower Base to remember the key materials.

Process: Gaseous halides of silica and dopants are combined in Vapor Phase Oxidation.

2. Vapor Phase Oxidation

Converts gaseous materials into solid glass particles (soot) for fiber production. Two methods:

- Flame Hydrolysis: Uses flame to oxidize gases into soot.

- Chemical Vapor Deposition (CVD): Deposits soot inside a tube or on a surface.

Mnemonic: "Flaming CVD" – Picture a flame (Flame Hydrolysis) and a chemical vapor cloud (CVD) creating glass soot.

3. Types of Glass Used in Fiber Fabrication

| Material | Use | Properties |

| Silica (SiO₂) | Most common for optical fibers | Low loss, ideal for telecom |

| Fluorozirconate/Fluoroaluminate | Special fibers | Good for infrared transmission |

| Chalcogenide Glasses | Long-wavelength infrared | High Refractive Index (RI ≈ 3.0) |

| Crystalline Materials (e.g., Sapphire) | Special applications | Durable, infrared transmission |

Mnemonic: "SFCC" – Silica, Fluoride, Chalcogenide, Crystalline. Imagine a Shiny Fiber Cable Core to recall these materials.

4. Refractive Index (RI)

- Silica/Fluoride Glasses: RI ≈ 1.5 (moderate).

- Chalcogenide Glasses: RI ≈ 3.0 (very high).

- Core vs. Cladding: RI difference is kept < 1% to ensure Total Internal Reflection, preventing light leakage.

Mnemonic: "1.5 for Silica, 3 for Chalcogenide" – Think "1.5 = Simple Silica, 3 = Complex Chalcogenide".

5. Basic Principle of Fiber Fabrication

- Process: Chemical reactions produce oxides (e.g., SiO₂), deposited as glass layers on a substrate (glass rod/tube) or inside a hollow tube via successive layering.

- Dopant Control: Gradually adjust dopant concentration to create desired Refractive Index Profile (e.g., graded index for specific fibers).

- Output: A solid glass rod or hollow tube, collapsed into a preform (a thick glass rod).

Mnemonic: "Layer, Dopant, Preform" – Imagine layering dough, adding spices (dopants), and baking a preform loaf.

6. Silica in Fiber Fabrication

- Why Silica?

- Excellent optical transmission, especially in near-infrared (1.55 µm or 1550 nm).

- Low absorption and scattering (~0.2 dB/km loss).

- Achieved using ultra-pure silica.

Mnemonic: "Silica Shines at 1550" – Picture silica as a shiny star glowing brightest at 1550 nm.

7. Silica Glass Fiber: Fiber Fabrication Process (Two Stages)

- Preform Fabrication: Create a thick glass rod with precise refractive index profile.

- Fiber Drawing: Heat and pull the preform into thin fiber.

Stage 1: Preform Fabrication

Method: Chemical Vapor Deposition (CVD), specifically Inside Vapor Deposition.

- Steps:

- Use a hollow glass tube (~40 cm long) as a substrate, rotated in a lathe.

- Inject SiCl₄ + O₂ (and dopants like GeCl₄) into the tube.

- Heat with a hydrogen burner (~1600°C) to form SiO₂ soot (fine glass particles).

- Soot deposits on the tube’s inner surface (soot deposition).

- Gradually build layers, adding dopants to form core (higher RI) and cladding (lower RI).

- Heat to 2000°C to collapse the tube into a solid preform rod.

Core vs. Cladding Techniques:

| Technique | Core Material | Cladding Material |

| Technique 1 | Doped SiO₂ (Ge, Al, P, Ti) | Pure SiO₂ |

| Technique 2 | Pure SiO₂ | Doped SiO₂ (F, B) |

Mnemonic: "Soot to Solid" – Think of soot piling up inside a tube, then solidifying into a preform rod.

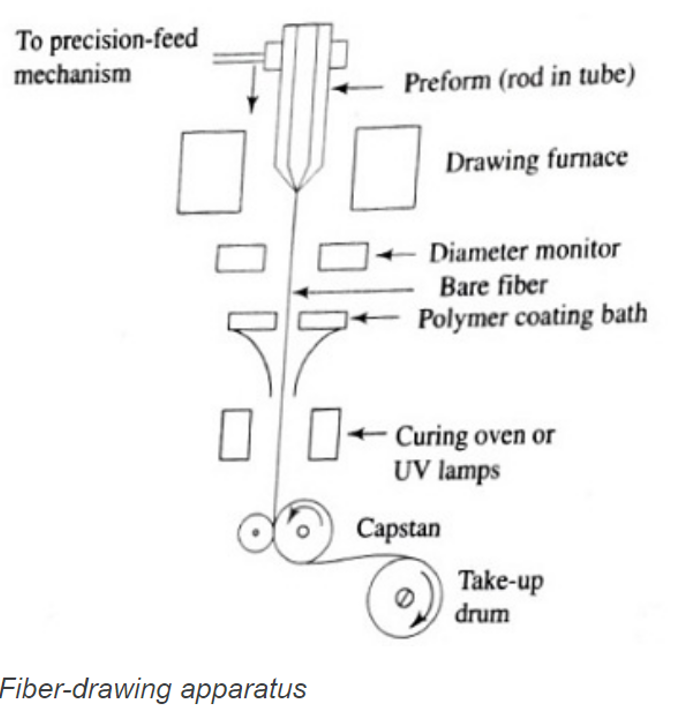

Stage 2: Fiber Drawing Process

Steps:

- Place preform in a Drawing Tower.

- Heat the preform’s tip (~2000°C) using a gas burner or graphite heater until it softens.

- Pull the softened glass into a thin fiber (like pulling taffy).

- Monitor fiber diameter with a Diameter Monitor to maintain ~125 µm, adjusting pulling speed.

- Apply UV-curable polymer coating to protect the fiber.

- Cure coating with UV light.

- Use a Capstan to control pulling speed/tension.

- Wind the fiber onto a Take-up Reel.

Mnemonic: "Heat, Pull, Coat, Reel" – Imagine heating a candy rod, pulling it thin, coating it with chocolate, and reeling it up.

8. Liquid Phase (Melting) Method (Rod-in-Tube Method)

Steps:

- Create a core glass rod (for light transmission).

- Insert the rod into a cladding glass tube to form a preform.

- Heat the preform in a drawing furnace (~2000°C).

- Pull into a thin fiber (~125 µm diameter).

- Monitor diameter and adjust pulling speed.

- Apply polymer coating, cure with UV light.

- Wind onto a reel.

Note:

- A 1-meter preform yields 20-30 km of fiber in 2-3 hours.

- Limitation: Batch process, not suitable for continuous production.

Mnemonic: "Rod in Tube, Heat, Pull" – Picture a rod sliding into a tube, heated, and pulled like a straw.

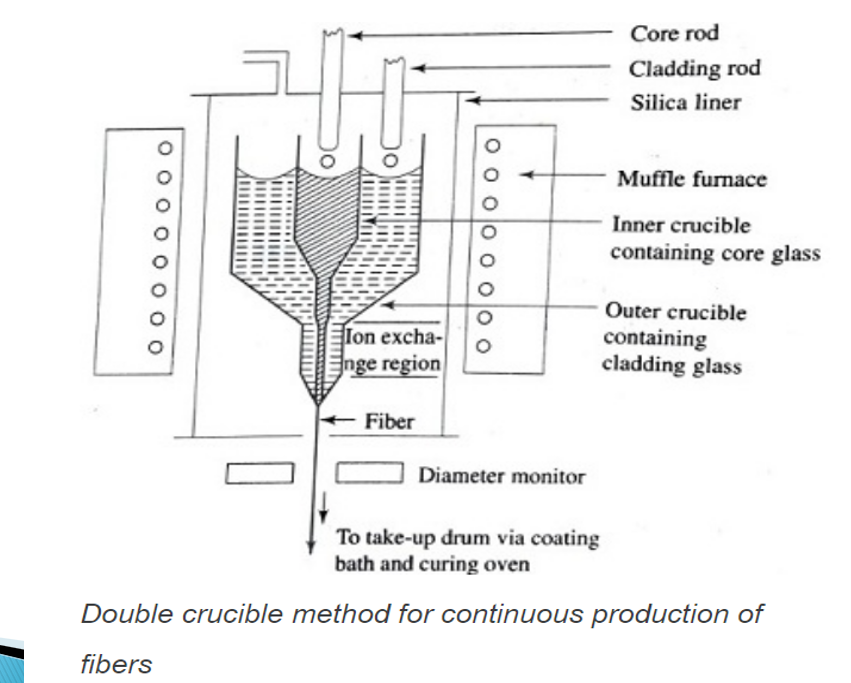

9. Double Crucible Method

Use: Continuous fiber manufacturing.

Setup: Two concentric platinum crucibles in a muffle furnace (800-1200°C).

Steps:

- Place core glass in the inner crucible, cladding glass in the outer crucible.

- Heat to melt both glasses.

- Molten glass flows through nozzles at the crucible bottoms, forming a core-cladding fiber.

- Apply polymer coating and wind onto a reel.

- Achieve graded index via dopant diffusion between core and cladding.

Mnemonic: "Double Crucible, Melt, Flow" – Imagine two nested pots melting glass, flowing out like syrup into a fiber.

Topic 02: Light Emitting Diode (LED)

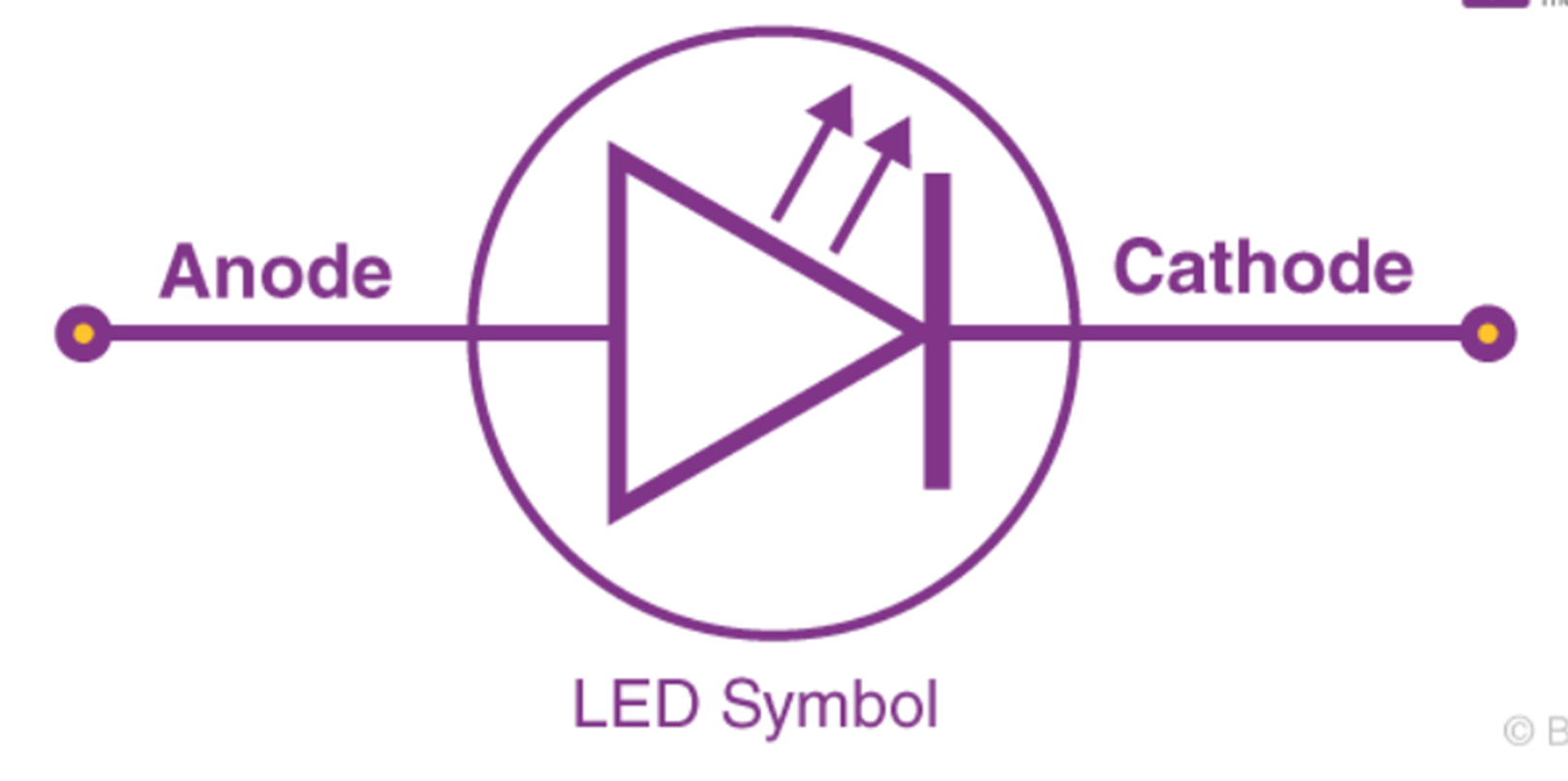

1. Definition of LED

An LED (Light Emitting Diode) is a semiconductor p-n junction device that emits light when forward-biased. It converts electrical energy into optical energy through electron-hole recombination.

- It emits light only when forward biased.

- Commonly used in communication and display systems.

Mnemonic:

"LED = Light Emission through Drift"

- L → Light

- E → Electron-hole recombination

- D → Drift in forward bias

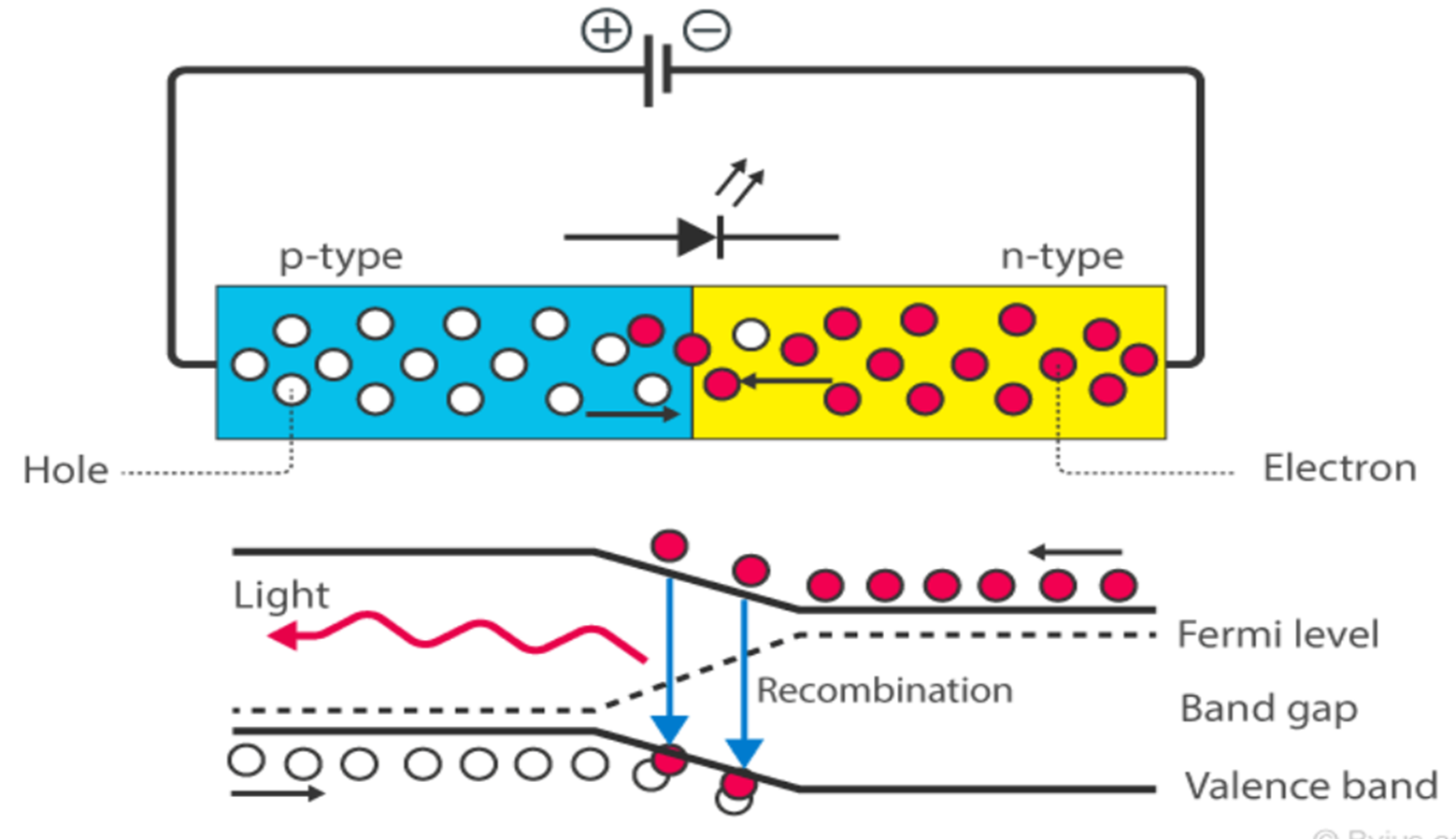

2. Working Principle of LED

- When forward biased, electrons move from the n-region to p-region, and holes move from p to n.

- At the junction, they recombine.

- This recombination releases energy in the form of photons (light).

- The color of the emitted light depends on the bandgap energy of the semiconductor.

3. Quantum Theory and LED

According to quantum theory:

- When an electron jumps from a higher energy level (conduction band) to a lower level (valence band), it emits a photon.

Formula:

Where:

= Bandgap energy (Joules)

= Planck’s constant =

= Frequency of emitted light (Hz)

= Wavelength of emitted light (m)

= Speed of light =

Key point:

- Wavelength λ is inversely proportional to energy gap Eg

4. Why LEDs Use Compound Semiconductors (Not Si or Ge)

- Silicon (Si) and Germanium (Ge) are indirect bandgap semiconductors.

- Electron-hole recombination does not produce visible light.

- Energy is emitted as heat or infrared radiation.

- LEDs require direct bandgap semiconductors (e.g., GaAs, GaP) to emit visible photons.

5. Steps of LED Operation

| Step | Description |

| 1 | Apply forward bias voltage |

| 2 | Electrons and holes recombine |

| 3 | Photon (light) is emitted |

| 4 | Photon energy is E=hcλE = \frac{hc}{\lambda}E=λhc |

Mnemonic:

"BREE" → Bias, Recombine, Emit, Energy

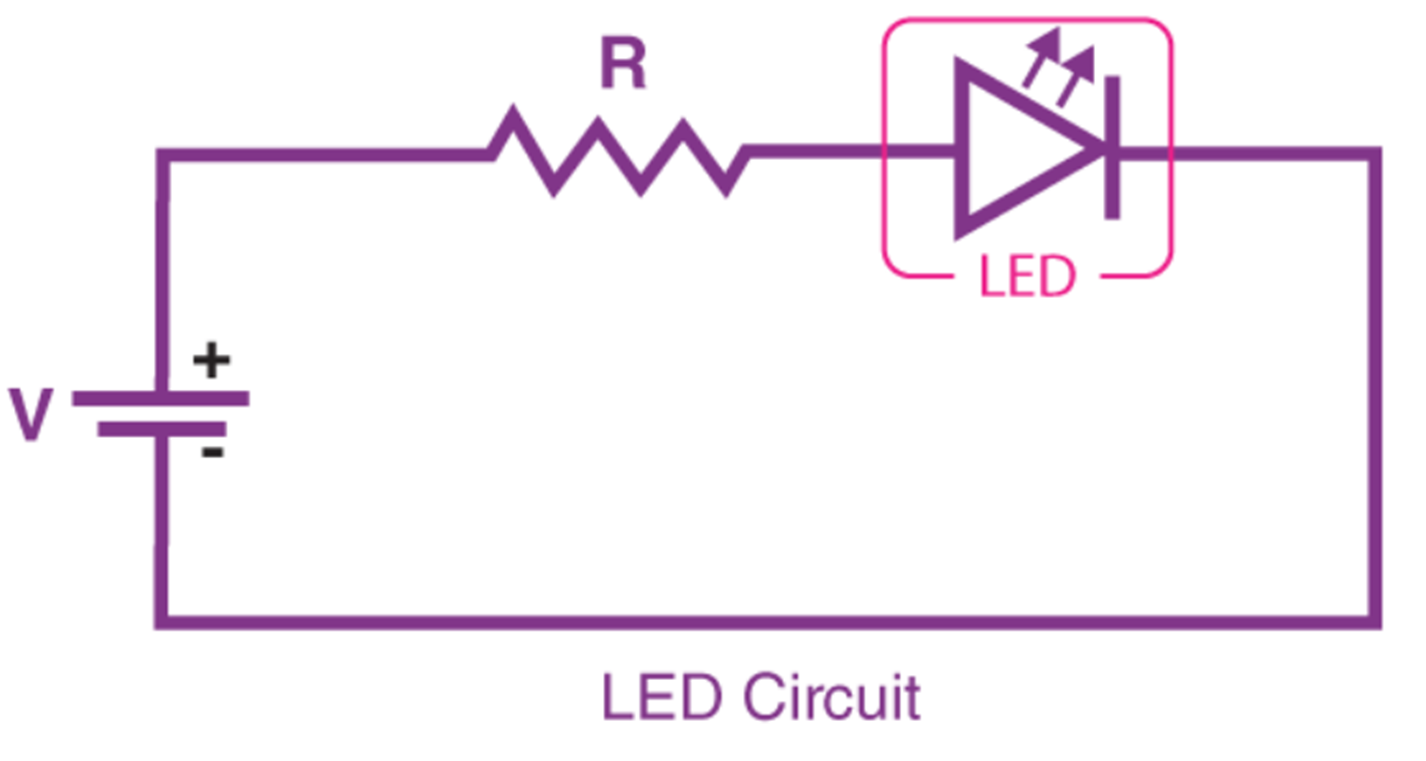

6. LED Biasing Circuit

- LEDs require current-limiting resistors to avoid excessive current.

- Operating voltage: 1V to 3V

- Operating current: 20 mA to 100 mA

Formula for current:

Where:

- I_F = Forward current

- V_s = Source voltage

- V_D = LED voltage drop

- R_s = Series resistor

Mnemonic:

"IF = V over R" – Apply Ohm’s Law

7. Materials Used and LED Colors

| Material | Emitted Color |

| GaAs | Infrared |

| GaAsP | Red, Orange |

| AlGaAsP | Bright Red, Orange, Yellow |

| GaP | Red, Yellow, Green |

| AlGaP | Green |

| GaN | Green, Emerald Green |

| GaInN | Blue-Green, Blue, UV |

| SiC | Blue (substrate) |

| ZnSe | Blue |

| AlGaN | Ultraviolet |

Mnemonic:

"Great Artists Always Paint Green Gardens In Soft Zonal Areas"

8. Differences Between Diode and LED

| Feature | Diode | LED |

|---|---|---|

| Purpose | Conduct current | Emit light |

| Emission | None | Visible/Infrared light |

| Material | Si, Ge | GaAs, GaP, etc. |

| Application | Rectifiers, switches | Indicators, displays |

| Light Source | No | Yes |

Mnemonic:

"Diode for Direction, LED for Light"

9. Important Characteristics of LEDs

| Property | Value |

|---|---|

| Operating Voltage | 1V – 3V |

| Operating Current | 20 mA – 100 mA |

| Response Time | Very fast (ns) |

| Works in | Forward bias only |

| Light Emission | Photon-based |

| Color Determination | By bandgap |

10. Advantages of LEDs

- Compact size and low cost

- Low power consumption

- High efficiency

- Long life : Up to 50,000–100,000 hours.

- Instant on/off: No warm-up time, instant on/off.

- Environmentally friendly: Minimal harmful materials (e.g., no mercury).

- Operates well at low temperature

- Directional light

- Controllable brightness : Vivid, accurate colors.

- High reliability

Mnemonic:

"SPEED COLD LIFE"

- S: Small size

- P: Power efficient

- E: Eco-friendly

- E: Easily controlled

- D: Directional

- C: Color quality

- O: On instantly

- L: Long life

- D: Durable

- E: Economical

11. Disadvantages of LEDs

- Temperature sensitive

- Light quality may vary

- Efficiency drops at high voltage

- Must use correct polarity

- Sensitive to overheating

- Some colors attract insects

Mnemonic:

"TEMPLED"

- T: Temperature sensitive

- E: Efficiency drops

- M: May vary in color

- P: Polarity-sensitive

- L: Light attracts insects

- E: Easily damaged by heat

- D: Degrades with time

12. Applications of LEDs

- Residential and industrial lighting

- Mobile and laptop screens

- Digital displays and signboards

- Traffic lights

- Television displays

- Automotive headlights and tail lights

- Optical communication (fiber)

- Remote control indicators

Mnemonic:

"LED MOTORS"

- L: Lighting

- E: Electronics

- D: Display

- M: Motor vehicle lights

- O: Outdoor signage

- T: Traffic signals

- R: Remote indicators

- S: Screens and monitors

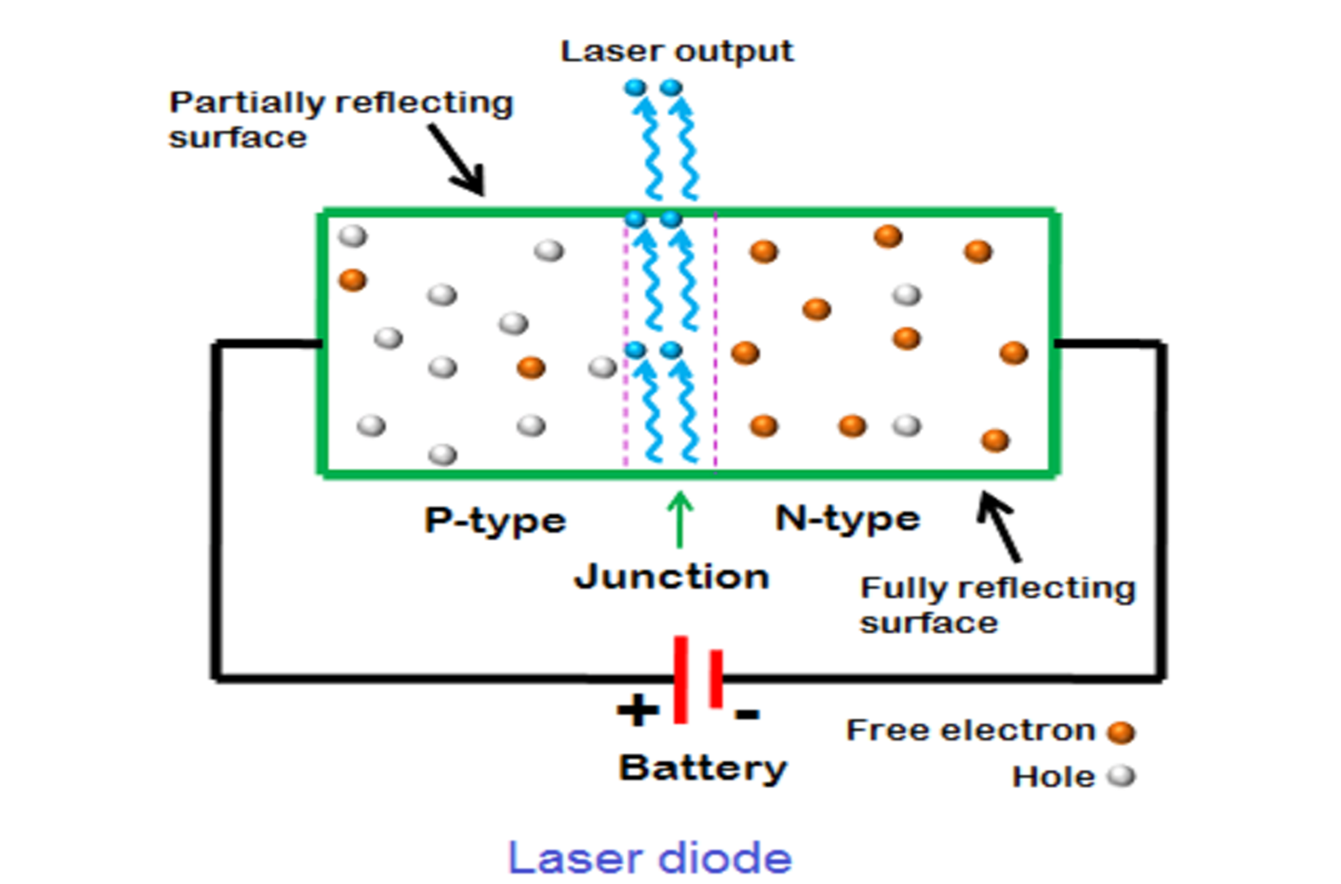

Topic 03: Laser Diode

Definition: A Laser Diode (LD), also known as a Semiconductor Laser, Junction Laser, or Injection Laser, is an optoelectronic device that converts electrical energy into a coherent light beam via stimulated emission. It is small, cost-effective, and widely used in optical communication.

Mnemonic: "LD = Little Laser Dynamo" – Picture a tiny dynamo producing a powerful laser beam.

1. Working Principles of Laser Diode

Laser diodes operate based on three fundamental principles:

a. Stimulated Emission

- Process: An incoming photon stimulates an excited electron to drop to a lower energy state, releasing a second photon with the same wavelength, phase, and direction.

- Result: One photon generates two photons, amplifying light to produce a coherent beam.

- Contrast with Other Emissions:

- Stimulated Absorption: Electrons absorb external energy (e.g., DC voltage) and jump to the conduction band.

- Spontaneous Emission: Excited electrons naturally drop to a lower state, emitting random photons.

Mnemonic: "Stimulated = Twin Photon Team" – Imagine one photon teaming up to create a twin, amplifying light.

b. Population Inversion

- Definition: A state where the number of electrons in a higher energy state (conduction band) exceeds those in the lower energy state (valence band).

- Importance: Essential for more stimulated emission than absorption, enabling light amplification.

- Achieved By: Pumping energy (e.g., electrical current) into the gain medium.

Mnemonic: "Population Inversion = Excited Electron Majority" – Picture a majority of electrons excited at a high-energy party.

c. Cavity Resonance

- Description: The laser diode has an optical cavity with two reflective surfaces: one fully reflective (100%) and one partially reflective (~95%).

- Function: Photons bounce between mirrors, triggering more stimulated emission, amplifying light.

- Output: A narrow, high-intensity beam escapes through the partially reflective mirror.

Mnemonic: "Cavity = Mirror Bounce Booster" – Imagine light bouncing between mirrors to boost intensity.

Extra Info: Some lasers (e.g., nitrogen laser) produce a beam with a single pass through the gain medium, but most laser diodes require a cavity for sustained lasing.

2. Types of Emission

| Type | Description |

|---|---|

| Stimulated Absorption | Electrons absorb external energy and jump to the conduction band. |

| Spontaneous Emission | Excited electrons naturally recombine with holes, emitting random photons. |

| Stimulated Emission | An external photon triggers recombination, producing two photons with identical phase and direction. |

Mnemonic: "ABS: Absorb, Spark, Stimulate" – Absorb energy, Spark randomly, Stimulate coherently.

3. Steps of Laser Diode Operation

- Energy Absorption:

- DC voltage excites electrons from the valence band to the conduction band, creating holes in the valence band.

- Spontaneous Emission:

- Some electrons recombine with holes, emitting random photons.

- Stimulated Emission:

- Spontaneous photons stimulate other excited electrons to recombine, producing two photons per incident photon.

- Photons bounce between reflective surfaces, amplifying light.

- Light Output:

- A coherent, high-intensity beam escapes through the partially reflective mirror.

Mnemonic: "Absorb, Spark, Stimulate, Beam" – Absorb energy, Spark photons, Stimulate more, Beam out.

4. LED vs. Laser Diode

| Feature | LED | Laser Diode |

|---|---|---|

| Light Type | Incoherent | Coherent |

| Bandgap | Indirect/Direct | Direct |

| Light Propagation | Diffused | Directional, concentrated |

| Intensity | Low | Very high |

| Applications | Indicator lights, displays | CD/DVD drives, fiber optics |

| Cost | Cheaper | More expensive |

Mnemonic: "LED Diffuses, LD Directs" – LEDs scatter light, LDs shoot a direct beam.

Extra Info: Laser diodes use direct bandgap semiconductors (e.g., GaAs) for efficient photon emission, unlike LEDs, which may use indirect bandgap materials.

5. Population Inversion

- Definition: Occurs when more electrons are in the excited state than the ground state, essential for laser light production.

- Mechanism: Achieved by supplying external energy (e.g., current) to excite electrons.

Mnemonic: "PI = Pumped-Up Electrons" – Picture pumping electrons to a higher state.

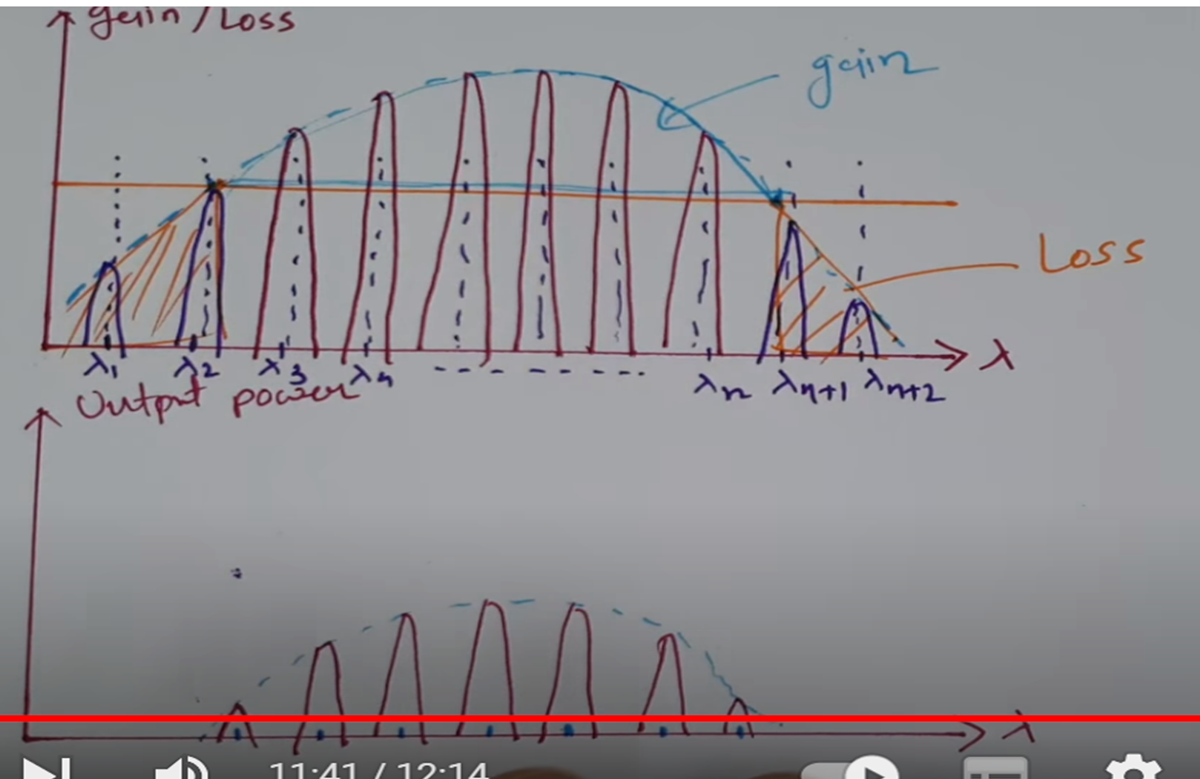

6. Cavity Resonance and Optical Resonator

- Structure: Two mirrors form an optical cavity:

- Fully reflective (100%) mirror reflects all light.

- Partially reflective (~95%) mirror allows some light to escape as a laser beam.

- Process: Photons bounce multiple times, triggering stimulated emission, amplifying light exponentially when gain > loss.

- Lasing Threshold: The minimum pump power needed to overcome cavity losses and start lasing.

- Gain Saturation: As beam power increases, each stimulated emission returns atoms to the ground state, reducing gain until equilibrium is reached (in continuous wave lasers).

Mnemonic: "Resonator = Reflective Ping-Pong" – Light plays ping-pong between mirrors to amplify.

Extra Info: The cavity ensures only specific wavelengths (resonant modes) are amplified, contributing to the laser’s monochromaticity.

7. Gain Medium

- Definition: The material (e.g., p-n junction in GaAs) that amplifies light via stimulated emission.

- Process: Absorbs pump energy (e.g., electrical current), exciting electrons to higher energy states, which then emit coherent photons.

Mnemonic: "Gain = Glowing Active Material" – Picture the active medium glowing with amplified light.

8. Laser Light Characteristics

| Characteristic | Description |

|---|---|

| Coherence | Photons have identical phase and direction. |

| Monochromaticity | Single wavelength (one color). |

| Directionality | Narrow, straight beam with minimal spreading. |

| High Intensity | Extremely powerful light output. |

- Beam Types: Gaussian, top-hat, Bessel, multimode transverse modes, optical vortex.

Mnemonic: "CMDI = Coherent, Mono, Directional, Intense" – Think CMDI Laser Beam.

Extra Info: The coherence and directionality make laser diodes ideal for optical communication, ensuring minimal signal loss over long distances.

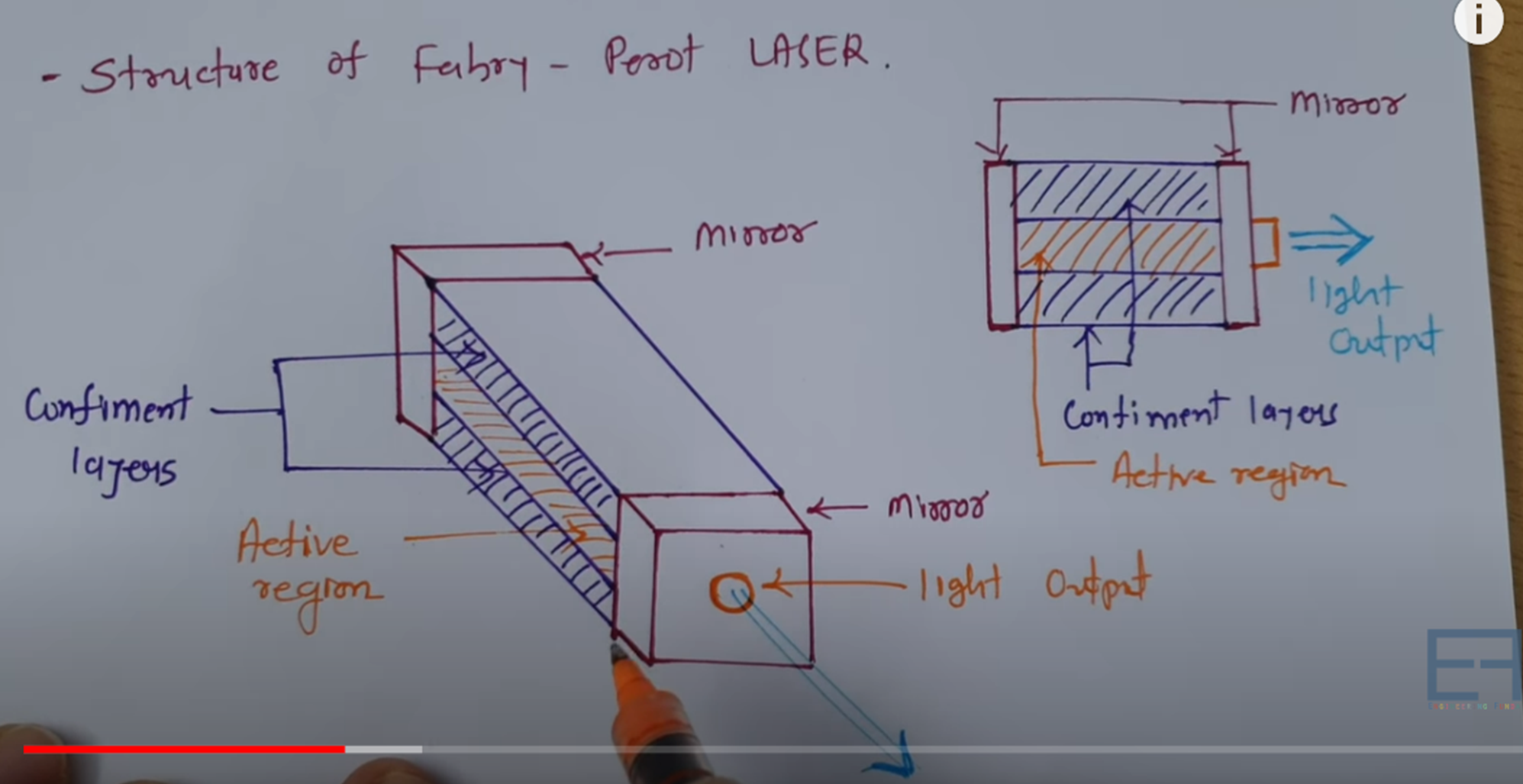

9. Fabry-Pérot Laser Diode

- Definition: The most common laser diode, using a Fabry-Pérot interferometer (two flat mirrors) as the resonator.

- Structure: A cavity with two mirrors creating standing waves for specific frequencies (longitudinal modes).

- Resonance Condition:

Where:

- f_n: nth harmonic frequency

- v: Speed of light in the medium

- L: Cavity length

- n: Mode number (integer)

- Operation: Only frequencies that form standing waves (integral multiples of half-wavelength) are amplified, producing lasing modes.

- Note: May produce multiple longitudinal modes, requiring stabilization for high-speed communication.

Mnemonic: "Fabry-Pérot = Flat Mirror Waves" – Picture flat mirrors creating standing waves.

Extra Info: The gain spectrum overlaps with resonant frequencies, determining which modes lase. Stabilization techniques (e.g., distributed feedback) can reduce multiple modes.

10. How Laser Diode Works

- DC Voltage Application: Electrons move from n-type to p-type, becoming excited.

- Spontaneous Emission: Some electrons recombine, emitting random photons.

- Stimulated Emission: Photons stimulate more recombination, producing coherent photons.

- Photon Bouncing: Photons bounce between mirrors, amplifying via stimulated emission.

- Laser Output: A coherent beam escapes through the partially reflective mirror.

Mnemonic: "Volt, Spark, Stimulate, Bounce, Beam" – Voltage sparks, stimulates, bounces, beams.

11. Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Simple construction | Not suitable for high-power applications |

| Lightweight | Highly temperature-sensitive |

| Cost-effective | — |

| Small size | — |

| Long lifespan | — |

| High efficiency | — |

| No external mirrors needed | — |

Mnemonic: "SLICE = Simple, Light, Inexpensive, Compact, Efficient" – Picture a slice of efficient laser tech.

Disadvantages: "Low Temp" – Low power, Temperature-sensitive.

Extra Info: Temperature control (e.g., thermoelectric coolers) is critical to maintain stable output and prevent degradation.

12. Applications of Laser Diode

- Optical disk drives (CD/DVD/Blu-ray)

- Barcode scanners

- Optical fiber communication

- Laser printers

- Medical instruments (e.g., eye surgery)

- Laser cutting and welding

- Laser pointers

- Military range-finding

- DNA sequencing

- Entertainment (laser shows)

Mnemonic: "FIBER-DISC" – Fiber optics, Instruments, Barcode, Entertainment, Range-finding, Disk drives, Surgery, Cutting.

Extra Info: In optical communication, laser diodes are preferred over LEDs due to their narrow spectral width and high modulation speed, enabling high data rates.

13. Additional Key Information for Exam

- Lasing Threshold: The minimum current required to achieve population inversion and start lasing. Below this, the LD emits incoherent light (like an LED).

- Gain Saturation: In continuous wave (CW) lasers, gain decreases as more atoms return to the ground state, stabilizing the output power.

- Materials: Typically gallium arsenide (GaAs) or related compounds, with doping agents like selenium, aluminum, or silicon.

- Response Time: Laser diodes have fast rise/fall times (nanoseconds), ideal for high-speed data transmission.

- Safety: Laser light can cause eye damage; proper precautions (e.g., shielding) are essential.

- Comparison with Gas Lasers: Laser diodes are smaller, cheaper, and more efficient than gas lasers (e.g., He-Ne), but have lower power output.

Topic: Photodiode

Definition: A Photodiode is an optical detector that converts light (photons) into an electrical signal (current). It is widely used in fiber optic communication, sensors, light measurement, and security systems.

Mnemonic: "Photodiode = Photon-to-Current Device" – Picture a device turning photons into a current flow.

1. Optical Detectors

- Definition: Devices that detect light and convert it into electrical signals.

- Applications: Fiber optic communication, sensors, light intensity measurement, security systems.

Mnemonic: "Optic Detectors = Light-to-Signal Machines" – Imagine light being transformed into signals.

Extra Info: Photodiodes are preferred in optical communication due to their high sensitivity and fast response, enabling reliable data detection.

2. p-n Photodiode

Definition

A p-n Photodiode is a p-n junction diode that generates a reverse current when exposed to light under reverse bias. The current increases with light intensity.

Mnemonic: "p-n = Photon-Triggered Current" – Picture photons triggering current in a p-n junction.

Structure and Working Principle

- Structure: A reverse-biased p-n junction diode.

- Process:

- When light hits the depletion region, it creates electron-hole pairs.

- The electric field in the depletion region separates electrons and holes, generating a photocurrent.

- Higher light intensity → more pairs → higher current and lower resistance.

- Light Interaction:

- Light in the depletion region produces photocurrent.

- Light in p or n regions (far from depletion) is lost as heat.

Key Characteristics

| Characteristic | Description |

|---|---|

| Responsivity | Ratio of generated current to incident light power (A/W). Varies with wavelength. |

| Dark Current | Small current produced without light, contributing to system noise. |

| Response Time | Time for charge carriers to cross the junction. Wider depletion region → faster response. |

| Breakdown Voltage | Maximum reverse voltage before the diode risks damage. |

Mnemonic: "RDRB = Responsivity, Dark, Response, Breakdown" – Think RDRB for p-n traits.

Applications

- Alarm circuits

- Counter circuits

- Computer interface devices

Extra Info: p-n photodiodes are cost-effective but have lower sensitivity compared to other types, making them suitable for basic applications.

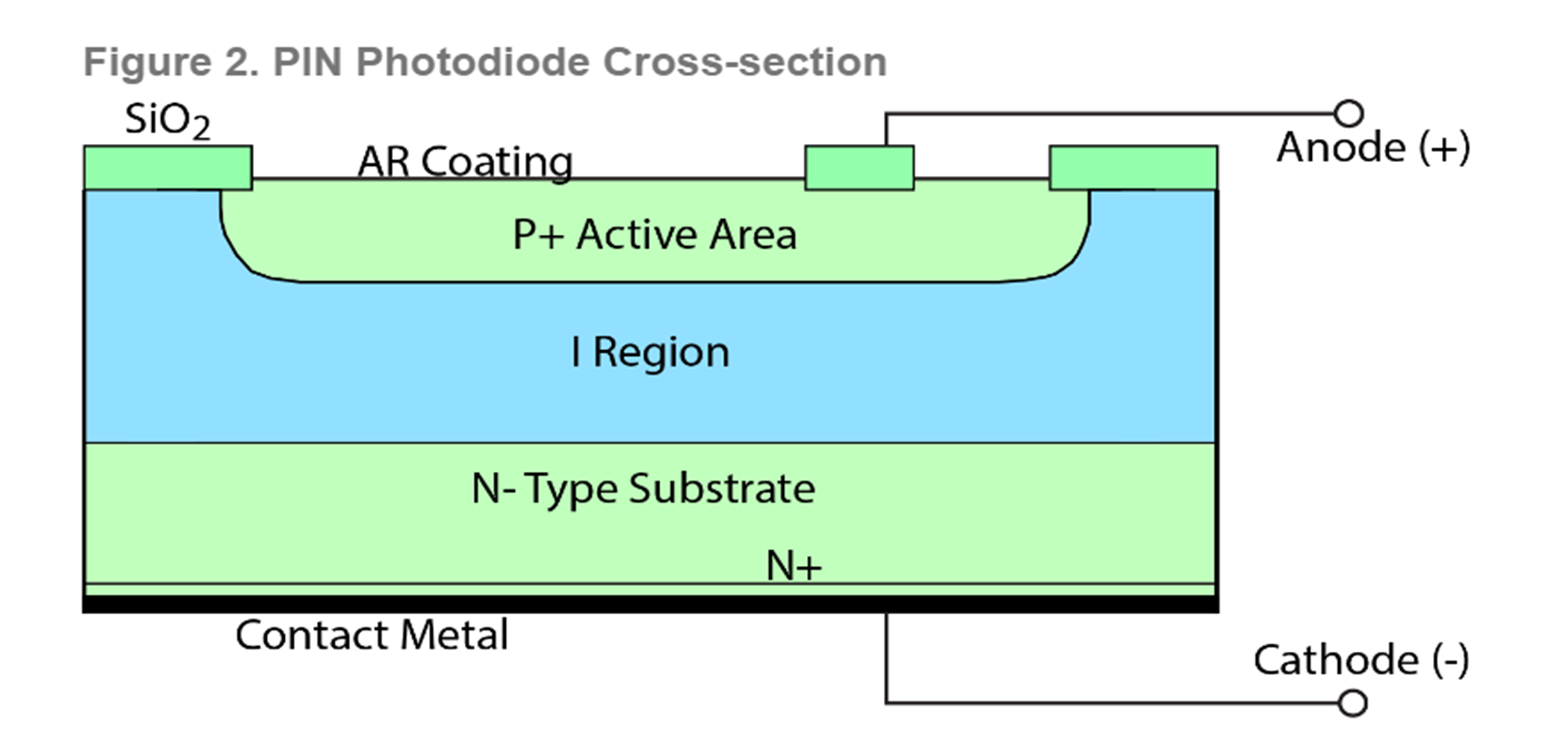

3. p-i-n Photodiode

Definition

A p-i-n Photodiode has a p-type, intrinsic (i), and n-type region, with the intrinsic layer increasing the depletion region size, improving speed and efficiency.

Mnemonic: "p-i-n = Photon-Intrinsic Powerhouse" – Picture an intrinsic layer boosting photon detection.

Structure and Working Principle

- Structure: p-type, thin intrinsic (undoped) layer (10–200 µm, high resistance), n-type.

- Process:

- The intrinsic layer enhances light absorption, generating more electron-hole pairs.

- Larger depletion region reduces capacitance and increases responsivity.

- Reverse bias enhances charge carrier separation, producing higher photocurrent.

Key Characteristics

| Characteristic | Description |

|---|---|

| High Response Speed | Large intrinsic region enables fast operation. |

| Low Capacitance | Intrinsic layer reduces capacitance, improving speed. |

| High Quantum Efficiency | More photons convert to electrons, enhancing efficiency. |

Mnemonic: "SRF = Speedy, Reduced-Capacitance, Efficient" – Think SRF for p-i-n perks.

Applications

- Fiber optic communication

- X-ray and gamma-ray detection

- RF and microwave circuits

- Photovoltaic cells and photodetectors

Additional Info

- Reverse Bias: Acts as a variable capacitor.

- Forward Bias: Acts as a variable resistor.

Extra Info: The intrinsic layer makes p-i-n photodiodes ideal for high-speed applications like optical receivers in fiber optic systems due to their low capacitance and fast response.

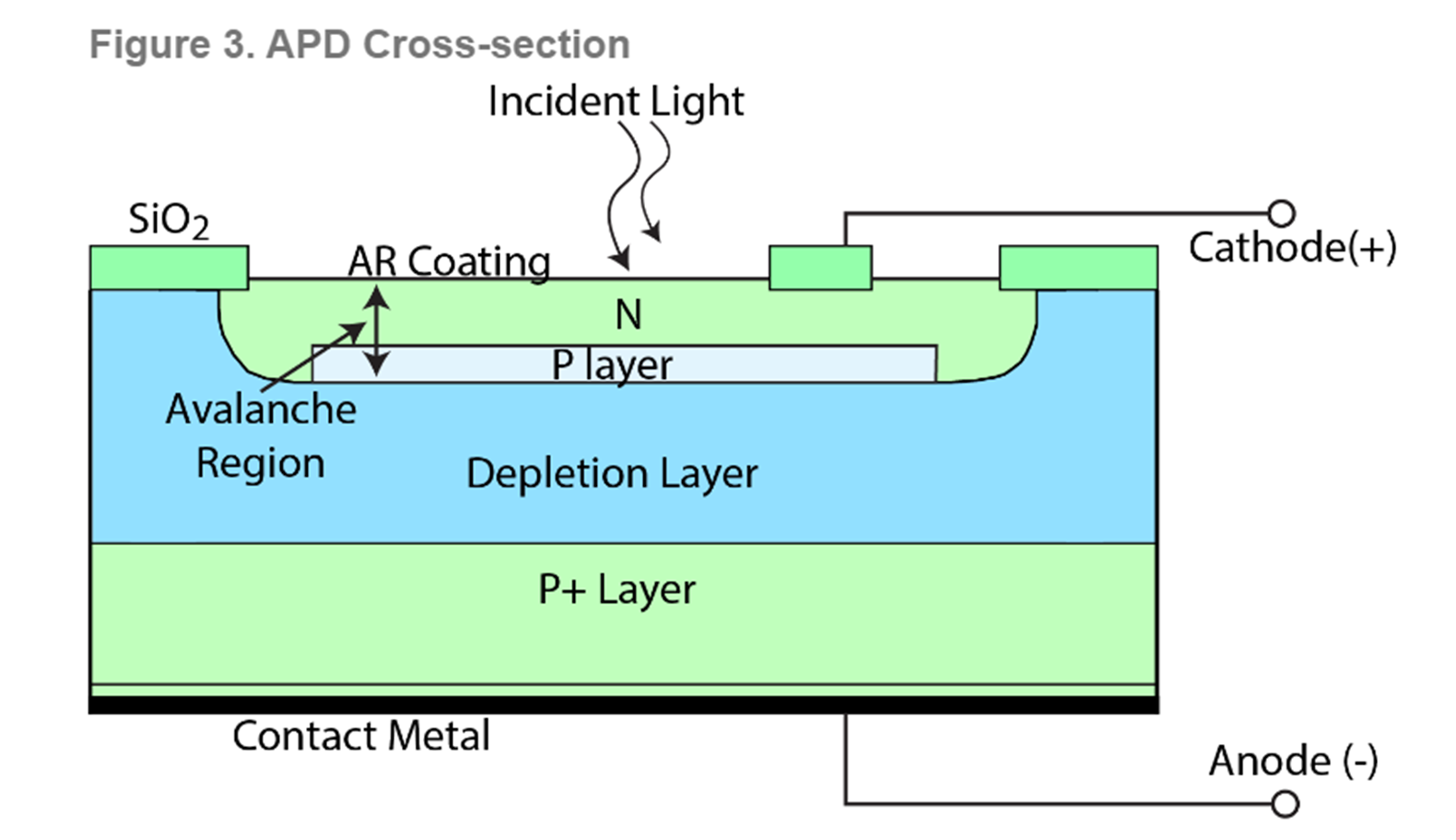

4. Avalanche Photodiode (APD)

Definition

An Avalanche Photodiode (APD) is a highly sensitive photodiode that uses the avalanche effect to multiply the photocurrent, producing significant current even with weak light.

Mnemonic: "APD = Avalanche Power Detector" – Picture an avalanche of electrons amplifying light detection.

Structure and Working Principle

- Structure: Includes p+, p, intrinsic (i), n, n+ regions.

- Process:

- Under high reverse bias (near breakdown), light generates electron-hole pairs.

- These carriers gain energy in a strong electric field, causing impact ionization (collisions create more pairs).

- This results in internal gain, amplifying the photocurrent significantly.

- Impact Ionization: Electrons accelerate, collide with atoms, and generate additional electron-hole pairs, creating a multiplication effect.

Key Characteristics

| Characteristic | Description |

| High Internal Gain | Avalanche effect multiplies current significantly. |

| High Responsivity | Produces large current from minimal light. |

| High Speed | Low transit time ensures fast response. |

| Higher Noise | Impact ionization increases noise, but signal-to-noise ratio remains good. |

Mnemonic: "GRIN = Gain, Responsivity, Intense, Noisy" – Think GRIN for APD traits.

Applications

- Weak light detection

- Fiber optic receivers

- Laser range finders

- Nuclear detection

Extra Info: APDs are used in low-light conditions (e.g., long-distance fiber optic links) but require precise voltage control to avoid excessive noise or damage.

5. LED vs. Photodiode

| Feature | LED | Photodiode |

| Function | Emits light | Detects light |

| Bias | Forward bias | Reverse bias |

| Conversion | Electricity → Light | Light → Electricity |

| Applications | Lighting, displays | Sensors, communication |

| Sensitivity | Low | High |

Mnemonic: "LED Shines, Photodiode Senses" – LEDs shine light, photodiodes sense it.

6. Comparison: p-n, p-i-n, and Avalanche Photodiode

| Feature | p-n Photodiode | p-i-n Photodiode | Avalanche Photodiode (APD) |

| Structure | p and n regions | p, intrinsic, n regions | p+, p, intrinsic, n, n+ regions |

| Depletion Region | Small | Large (due to intrinsic layer) | Large with high electric field |

| Bias Type | Reverse bias | Reverse bias | High reverse bias (near breakdown) |

| Light Absorption | Low | High | Highest (due to avalanche effect) |

| Responsivity | Low | Medium | Very high (internal gain) |

| Internal Gain | None | None | Yes (avalanche multiplication) |

| Current Output | Low | Higher | Highest |

| Speed | Slow | Fast (low capacitance) | Very fast (but some noise) |

| Noise | Low | Medium | High (due to impact ionization) |

| Cost | Low | Medium | High |

| Applications | Light sensors, counters | Fiber optics, X-ray detectors | Weak light detection, range finders |

Mnemonic: "p-n Simple, p-i-n Speedy, APD Super-Sensitive" – Picture p-n as basic, p-i-n as fast, APD as ultra-powerful.

7. Tips for Memorization

- p-n Photodiode:

- Simple, cheap, low current.

- Mnemonic: "p-n = Plain and Normal" – Basic light detector.

- p-i-n Photodiode:

- Intrinsic layer boosts absorption and speed.

- Mnemonic: "p-i-n = Intrinsic Speed King" – Fast and efficient.

- Avalanche Photodiode:

- High gain, sensitive to weak light, but noisy.

- Mnemonic: "APD = Avalanche Powerhouse" – Amplifies like an avalanche.

8. Additional Key Information for Exam

- Responsivity Formula: R = I_ph / P_opt (A/W), where I_ph is photocurrent and P_opt is optical power.

- Quantum Efficiency: Percentage of photons converted to electron-hole pairs. Higher in p-i-n and APD due to larger depletion regions.

- Dark Current Causes: Thermal generation of carriers, surface leakage, or tunneling. Minimized with proper material selection.

- Noise in APDs: Due to random impact ionization. Excess noise factor quantifies this, impacting signal quality.

- Wavelength Sensitivity: Photodiodes are optimized for specific wavelengths (e.g., 850 nm, 1310 nm, 1550 nm in fiber optics).

- Safety: High reverse bias in APDs requires careful handling to prevent breakdown.